AN230370 Precision analog channel subsystem in PSoC™ 4 HV PA family

About this document

Scope and purpose

This application note introduces you to the precision analog channel subsystem (PACSS) of PSoC™ 4 HV precision analog (PA) family MCUs. This application note also guides you to develop hardware and firmware design for battery monitoring application.

Intended audience

This document is intended for hardware and firmware design engineers.

Introduction

This application note provides an overview of the precision analog channel subsystem (PACSS) with the CY8C41xxLCE-HV4xx series from the PSoC™ 4 high-voltage (HV) precision analog (PA) family. PSoC™ 4 HV PA is a fully integrated programmable embedded system for battery monitoring and management. The system features an Arm® Cortex® M0+ processor and programmable and reconfigurable analog and digital blocks. To get a better understanding of the PACSS functionality and terminology used in this application note, it is a good idea to read "Section 21. Precision analog channel subsystem" of the

architecture reference manual (RM)

.

Precision analog channel subsystem overview

The PSoC™ 4 HV PA precision analog channel subsystem (PACSS) is a high-performance data acquisition subsystem consisting of two physical analog channels and four physical digital channels. The PACSS contains of the following blocks:

Analog delta-sigma modulator (DSM) system

Two analog channels

Channel multiplexer

Digital data system

Four digital channels (with/without FIR filter)

Data storage

Automatic gain control

Gain multiplexer

I/O components

Input multiplexer

Two high-voltage (HV) input dividers

On-die temperature sensor

External temperature sensor

shows the detailed block diagram of the PACSS measurement and acquisition system.

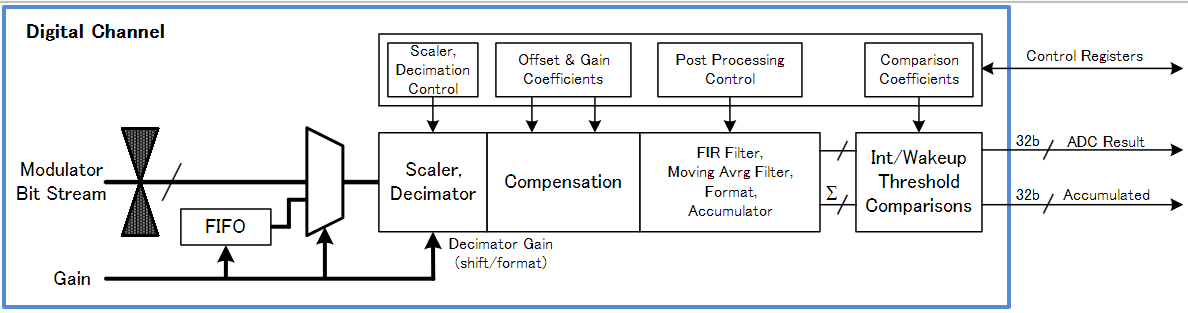

The analog DSM system is composed of the input multiplexer, programmable gain amplifier (PGA), anti-alias filter (AAF), diagnostic multiplexer, buffer, and a delta-sigma modulator. The digital data system is comprised of the scaler, decimator, FIR-type digital filter, accumulator, comparator, and offset and gain calibrations.

Also included in this subsystem are the auto gain correction (AGC) circuit and a temperature sensor with diagnostic capability. Each digital channel can quickly switch between input sources to create a "virtual" ADC that shares one of the analog channels, by using the digital data system. This “virtual” ADC channel can be used for diagnostic purposes.

The sequencer is used to generate control signals for performing all the functions of the channel.

Figure 1. PACSS measurement and acquisition system

Schematic and layout example

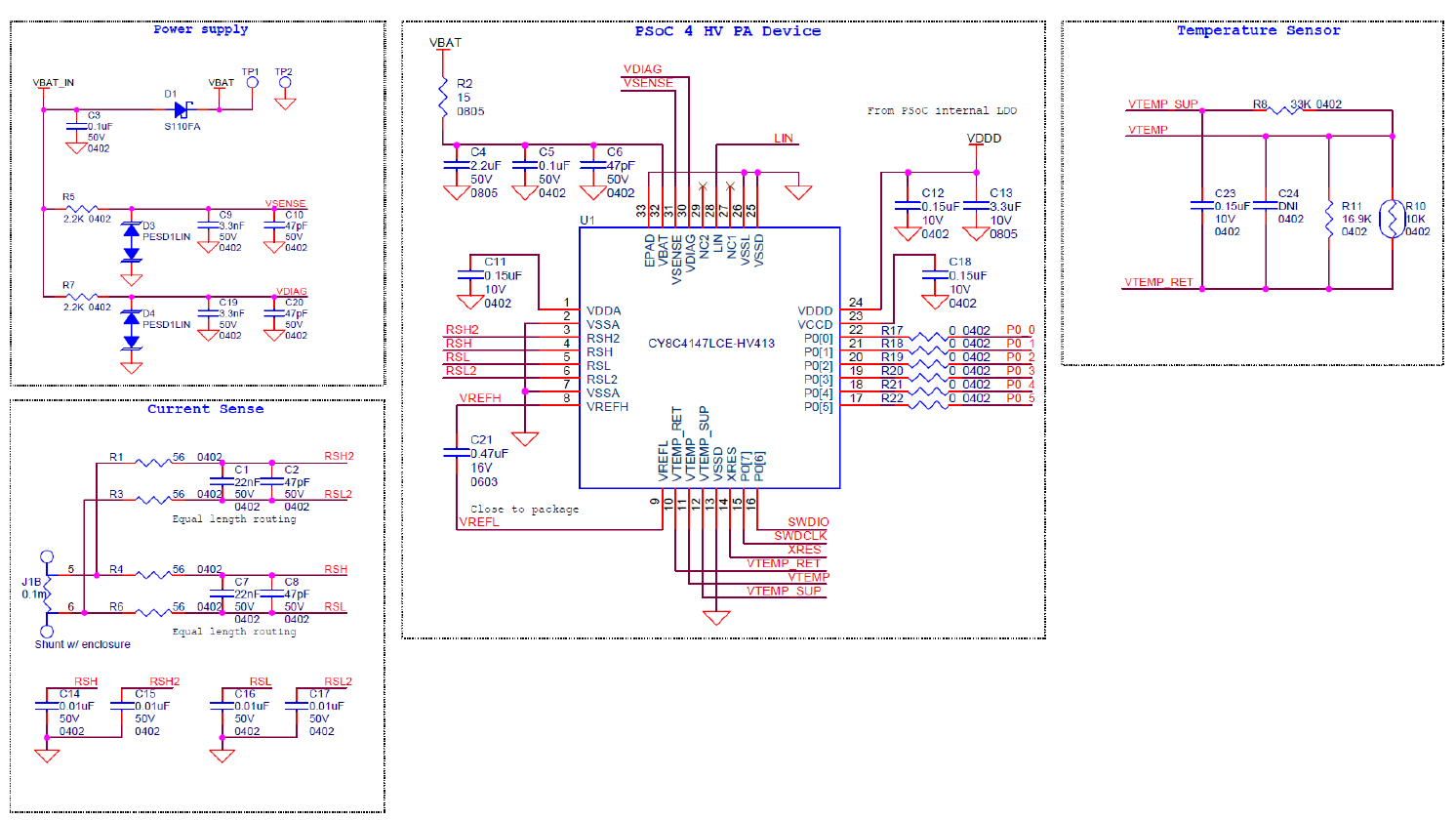

shows general schematic of external circuit for the PACSS system of the PSoC™ 4 HV PA MCU. See

AN230265 - Hardware design guide

for more information of power block.

Figure 2. General schematic of external circuit for PACSS system

Current sensor line

Schematic example

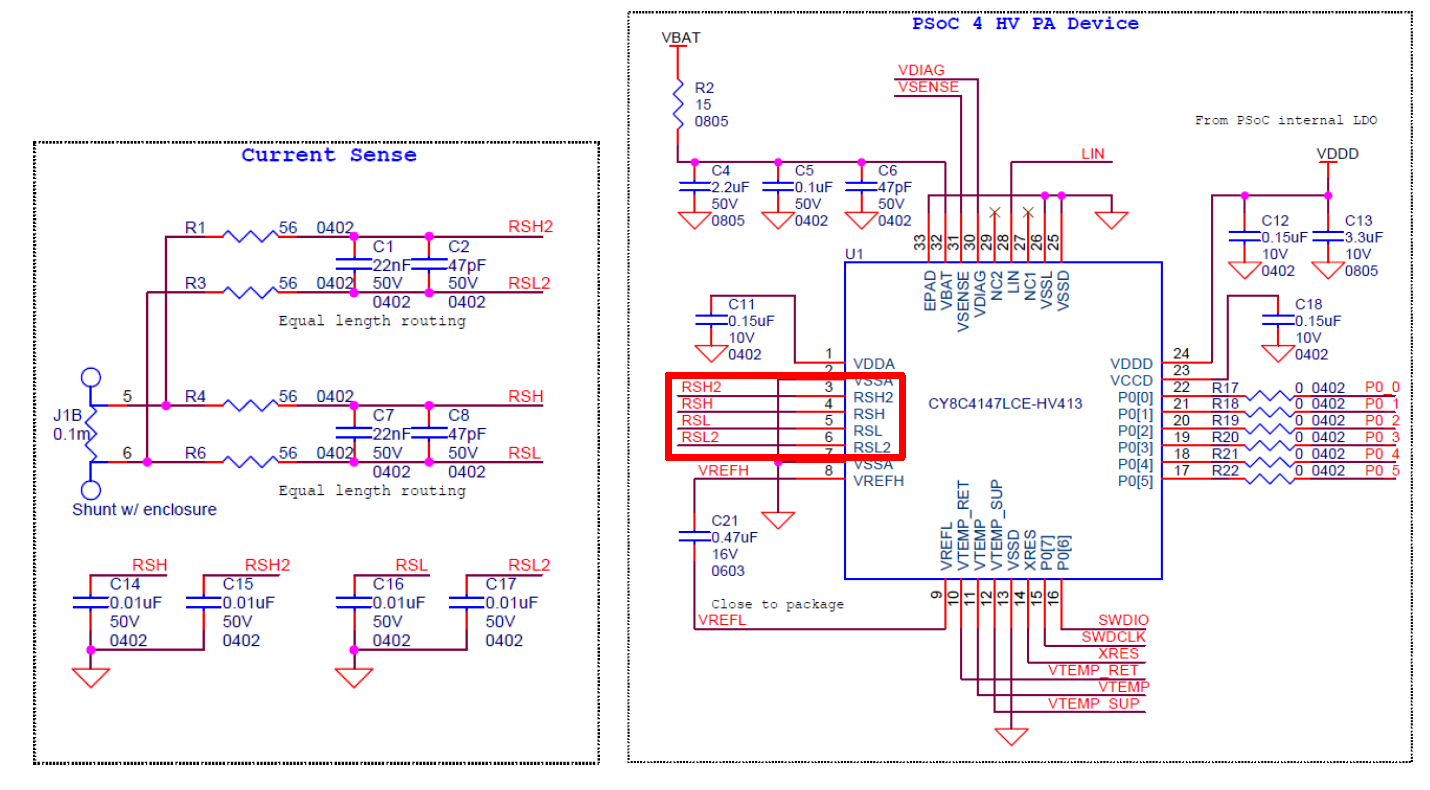

The current sensor line uses the RSH/RSL and RSH2/RSL2 terminals of the PSoC™ 4 HV PA MCU (See

Figure 3

). The RSH/RSL terminals are for the main line, and the RSH2/RSL2 terminals are for diagnostics. In the circuit example below, the sense output of one shunt resistor is routed to both RSH/RSL and RSH2/RSL2 terminals.

The external resistor and capacitor are optional low-pass filter components to attenuate any external noise for your application.

shows an example of external components.

Figure 3. Schematic example of current sensor line

Symbol | Overview | Parameter | ||

|---|---|---|---|---|

Value 1 | Value 2 | Remark | ||

R1, R3, R4, R6 | Resistor for external noise filter | 56 Ω ± 1% | > 1/10 W | |

C1, C7 | Capacitor for external noise filter | 22 nF X7R | > 50 V | |

C2, C8 | Capacitor for external noise filter | 47 pF C0G | > 50 V | |

C14, C15, C16, C17 | Capacitor for external noise filter | 0.01 μF X7R | > 50 V | |

Note: Max resistor value for current path (R1/R3/R4/R6): 500ohm.

Layout example

shows an example of current sensor line layout. Note that RSH2/RSL2 components are placed on bottom layer which are same position as RSH/RSL. This figure only shows top layer.

Figure 4. Layout example of current sensor line

Follow these guidelines for the design of the current sensor line circuit on the PSoC™ 4 HV PA MCU:

Match the length of each pair of RSHx and RSLx traces by routing on top or bottom layers of the PCB

Keep the width of RSHx/RSLx traces as the same as the IC Pad width

Do not use through-hole vias on the RSH/RSL trace if possible

Connect shunt resistor tracks from the inner edges of its solder pad to the IC as a differential pair

Keep the distance between RSHx and RSLx traces as the same as the IC terminal pitch if possible

Guard the entire pattern with GND

Place the GND layer under the sensor lines

Voltage sensor line

Schematic example

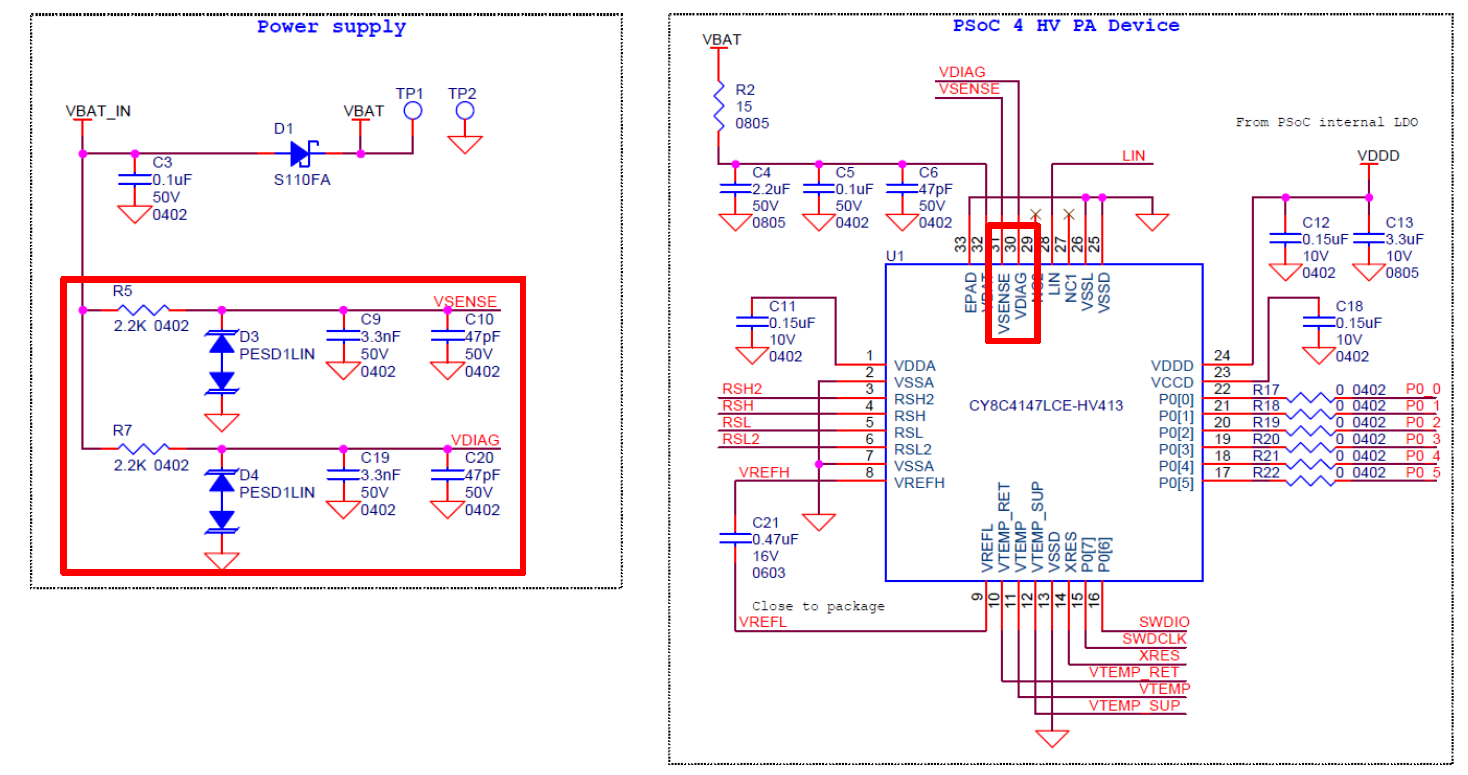

The voltage sense line uses the VSENSE and VDIAG terminals of the PSoC™ 4 HV PA MCU (See

Figure 5

). The VSENSE terminal is for the main line, while the VDIAG terminal is for diagnostic. In the circuit example below, the battery voltage input (VBAT) is divided into two and input to each terminal.

VSENSE and VDIAG inputs are normally connected directly to the battery with a series 2.2-kΩ resistor to measure the battery voltage; the capacitors are for low-pass filtering. The external transient voltage suppressors (TVS) diodes are to protect ESD noise. The TVS diodes are optional components.

shows an example of external components.

Figure 5. Schematic example of voltage sensor line

Symbol | Overview | Parameter | ||

|---|---|---|---|---|

Value 1 | Value 2 | Remark | ||

R5, R7 | Resistor for external noise filter | 2.2 kΩ ± 1% | > 1/10 W | |

D3, D4 | Transient voltage suppressor (TVS) | Bidirectional | Clamping voltage 44 V | Optional |

C9, C19 | Capacitor for external noise filter | 3.3 nF X7R | > 50 V | |

C10, C20 | Capacitor for external noise filter | 47 pF C0G | > 50 V | |

Note: Resistor values for voltage path (R5/R7): any deviation from nominal 2.2 kilohm needs to be associated with a reduction in accuracy.

Layout example

shows an example of the voltage sensor line layout.

Figure 6. Layout example of voltage sensor line

Follow these guidelines for the design of voltage sensor line circuit on the PSoC™ 4 HV PA MCU:

Length match the VSENSE and VDIAG traces as close as possible

Wire the VSENSE and VDIAG sensor lines from each VBAT point

Keep the trace width in the range of "0.127 mm" to the "IC terminal width"

Guard the entire pattern with GND

Place the GND layer under the sensor line

Temperature sensor line

Schematic example

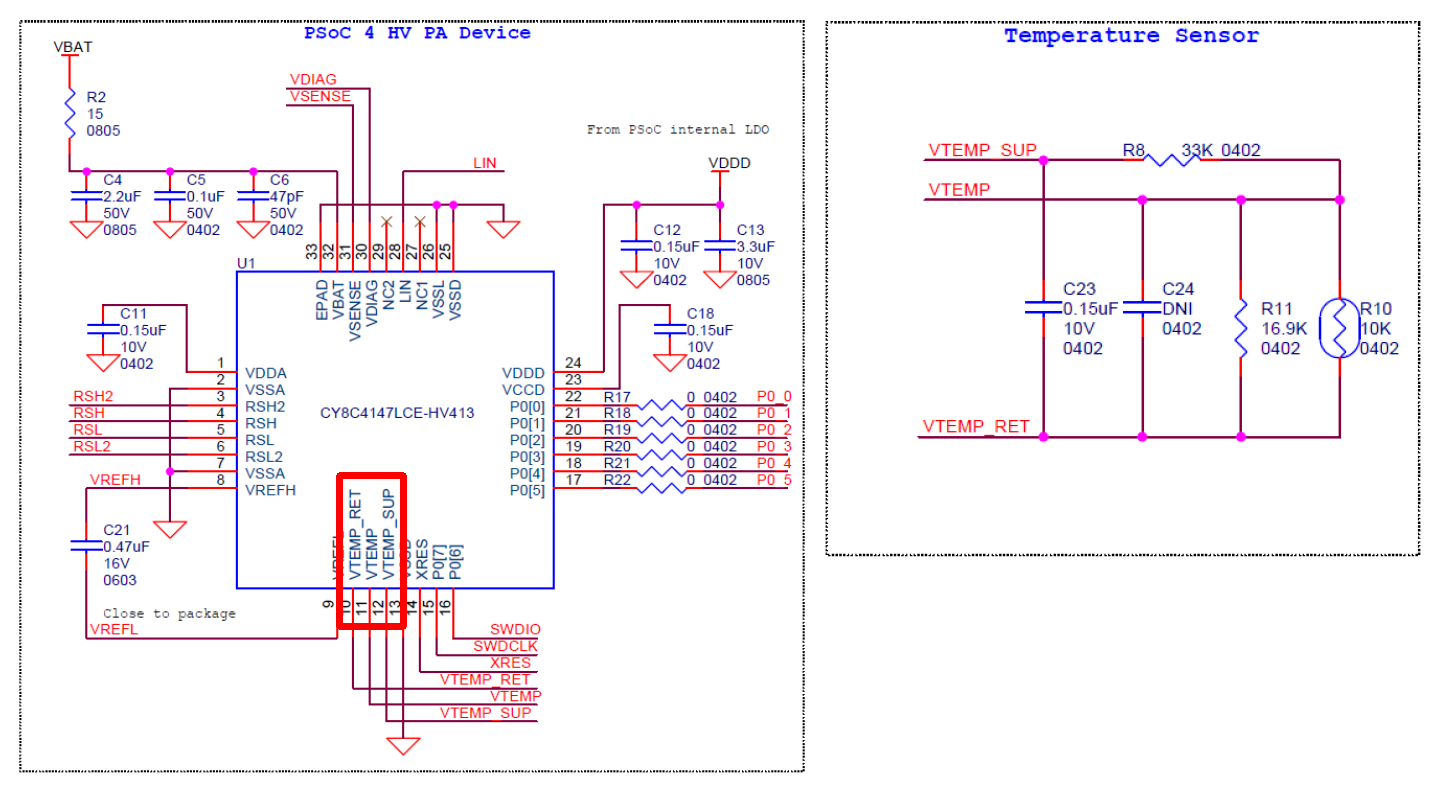

The temperature sensor line uses the VTEMP_SUP, VTEMP, and VTEMP_RET terminals of the PSoC™ 4 HV PA MCU (See

Figure 7

). VTEMP_SUP terminal is the power supply for the external temperature sensor, VTEMP is the temperature voltage input from the external sensor, and VTEMP_RET is the ground signal. In the circuit example below, the capacitors are added for decoupling the temperature sensor line.

The external voltage divider is selected to optimize temperature accuracy and will typically be comprised of a 33-kΩ and 16.9-kΩ fixed resistors (R) and a 10-kΩ nominal NTC thermistor RT (nominal NTC resistance is typically specified at 25°C).

shows an example of external components.

Figure 7. Schematic example of temperature sensor line

Symbol | Overview | Parameter | ||

|---|---|---|---|---|

Value 1 | Value 2 | Remark | ||

R8 | Resistor for voltage divider | 33 kΩ ± 1% | > 1/10 W | |

R10 | Thermistor | 10 kΩ ± 1% | > 1/8 W | |

R11 | Resistor for voltage divider | 16.9 kΩ ± 1% | > 1/10 W | |

C23 | Capacitor for external noise filter | 0.15 μF X7R | > 10 V | |

Layout example

shows an example of temperature sensor line layout.

Figure 8. Layout example of temperature sensor line

Follow these guidelines for the design of temperature sensor line circuit on the PSoC™ 4 HV PA MCU:

Place the thermistor (R10) as close to hot spot as possible

Keep the VTEMP_SUP, VTEMP, and VTEMP_RET at the same length as possible

Place the filter capacitor (C24) near the VTEMP and VTEMP_RET terminal

Keep the trace width in the range of "0.127 mm" to "IC terminal width"

Guard the entire pattern with GND

Place the GND layer under the sensor line

Battery minus and chassis GND connection

The PSoC™ 4 HV PA MCU can connect a battery minus and chassis GND to each current sensor line (RSH/RSL) and silicon GND (VSSA).

Figure 9

shows the general application block diagram for the intelligent battery system.

This example connects RSH and VSSA to chassis GND and connects RSL to battery minus. In this case, PACSS output will be #1 results in

Table 4

. The output data includes the consumed current of the PSoC™ 4 HV PA board as shown in green (when VSSA connects chassis GND). The polarity will be positive when discharging the battery and negative in charging the battery (When RSH is connected to chassis GND).

User can select the suitable GND connection for your application from

Table 4

.

Figure 9. General application block diagram for intelligent battery system

GND connection | Block diagram | PACSS output | ||

|---|---|---|---|---|

Polarity | Data | |||

1 | RSL - Battery minus RSH - Chassis GND VSSA - Chassis GND | Discharge: Plus Charge: Minus | Includes the consumed current of the PSoC™ 4 HV PA board | |

2 | VSSA - Battery minus RSL - Battery minus RSH - Chassis GND | Discharge: Plus Charge: Minus | Does not include the consumed current of the PSoC™ 4 HV PA board | |

3 | VSSA - Battery minus RSH - Battery minus RSL - Chassis GND | Discharge: Minus Charge: Plus | Does not include the consumed current of the PSoC™ 4 HV PA board | |

4 | RSH - Battery minus RSL - Chassis GND VSSA - Chassis GND | Discharge: Minus Charge: Plus | Includes the consumed current of PSoC™ 4 HV PA board | |

PACSS firmware configuration

Infineon provides the sample driver library (SDL) including startup code as sample firmware. The SDL provides a simple interface to access various peripherals and is used for system validation, hardware bring-up, benchmarks, feasibility studies, and demos. The SDL cannot be used for production purposes because it is not qualified with any automotive standards. The SDL integrates device header files, startup code, and peripheral drivers. The SDL contains a set of firmware drivers that provide APIs for accessing device-specific resources. See

AN230264 - Getting started with PSoC™ 4 HV PA family

for detailed SDL information.

The following sections explain the details of the application programming interface (API) and code examples for PACSS.

Attention: PACSS firmware configuration is created based on SDL version 3.0.0.

Peripheral drivers

Peripheral drivers are a set of firmware drivers that provide APIs for accessing the hardware. These APIs perform initialization and control activities of each peripheral.

Table 5 lists and describes the interface to each PACSS function. The peripheral drivers of PACSS are located in SDL path of:

C:/<user path>\ PSoC_Sample_Driver_Library_x.x.x\psoc4hvXXXk\src\drivers\adc\rev_b

Note: The PACSS has many registers to configure it. Table 5 is simplifying to only expose controls the customer should be using. See "low_level" and "config" folders in above path for more detailed functions.

See

API details

for more information.

Function | Description |

|---|---|

cy_adc.c | |

Cy_Adc_StartConversion() | Trigger a conversion on the enabled primary channels |

Cy_Adc_StartSecondaryConversion() | Trigger a secondary conversion on the enabled secondary channels |

Cy_Adc_GetResult() | Read the value in the result register of the specified channel |

Cy_Adc_GetAccumulatorResult() | Read the value in the accumulated result register of the specified channel |

Cy_Adc_ResetAccumulator() | Reset the accumulator to zero |

Cy_Adc_SetAccumulatorThreshold() | Set the accumulator Threshold |

Cy_Adc_SetGroundReference() | Set the ground connection for the high-voltage divider |

Cy_Adc_EnableSequencer() | Enable the ADC sequencer and AREF |

Cy_Adc_DisableSequencer() | Disable the ADC sequencer |

Cy_Adc_EnableReference() | Configure and enable the high-precision band gap reference (HPBGR) |

Cy_Adc_DisableReference() | Disable the high-precision band gap reference (HPBGR) |

Cy_Adc_GetInterrupt() | Get the specified digital channel's interrupt status |

Cy_Adc_GetInterruptMasked() | Get the DCHAN interrupt status masked by the enabled interrupts |

Cy_Adc_SetInterruptMask() | Enable the specified interrupt type for the specified channel |

Cy_Adc_ClearInterrupt() | Clear the specified interrupt |

Cy_Adc_GetInterruptCause() | Get the interrupt cause |

Cy_Adc_SetGainCorrection() | Set the gain correction factor for the specified DCHAN |

Cy_Adc_SetOffsetCorrection() | Set the offset correction factor for the specified DCHAN |

Cy_Adc_SetAGCGainCorrection() | Set the gain correction factor for the specified AGC gain level |

Cy_Adc_SetAgcOffsetCorrection() | Set the offset correction factor for the specified AGC gain level |

Cy_Adc_SetVrefLow() | Set the selection of the low reference of the DCHAN |

Cy_Adc_SetVrefHigh() | Set the selection of the high reference of the DCHAN |

cy_adc_init_achan.c | |

Cy_Adc_EnableAchan() | Enable the analog channel |

Cy_Adc_DisableAchan() | Disable the analog channel |

Cy_Adc_InitAchan() | Configure the analog channel |

ConfigureBuffer() | Configure the analog channel buffer |

ConfigurePga() | Configure the analog channel programmable gain array |

ConfigureReference() | Configure the analog channel reference |

ConfigureModulator() | Configure the analog channel modulator |

ConfigureTrigger() | Configure the analog channel primary/secondary trigger |

cy_adc_init_agc.c | |

Cy_Adc_EnableAgc() | Enable automatic gain correction (AGC) |

Cy_Adc_DisableAgc() | Disable automatic gain correction (AGC) |

Cy_Adc_InitAgc() | Configure automatic gain correction (AGC) |

ConfigureGainLevel() | Configure the gain level in memory, given the input configuration |

cy_adc_init_channel_chopping.c | |

Cy_Adc_InitAchanChannelChopping() | Configure the selected analog channel to perform channel chopping. |

cy_adc_init_dchan.c | |

Cy_Adc_EnableDchan() | Enable the digital channel |

Cy_Adc_DisableDchan() | Disable the digital channel |

Cy_Adc_InitDchan() | Configure the digital channel |

Cy_Adc_ConfigureGainLevel() | Configure the digital channel gain level settings |

ConfigureFIRFilter() | Configure the digital channel FIR filter coefficients |

Cy_Adc_ConfigureAafMode() | Configure the anti-alias filter |

cy_adc_init_temperature.c | |

Cy_Adc_EnableTemperature() | Enable the temperature sensor |

Cy_Adc_DisableTemperature() | Disable the temperature sensor |

Cy_Adc_InitTemperature() | Configure the temperature sensor |

Code example

Dual convert design (current/voltage)��

This example uses "current" channel (ACHAN0) that continuously measures the voltage across the RSH/RSL shunt resistor, and a second channel (ACHAN1) measures the voltage across the HV voltage divider with 16x attenuation. The current and voltage channel use the FIR filter. The results display in millivolts over the UART connection. The code example is located in SDL path of:

C:/<user path>

PSoC_Sample_Driver_Library_x.x.x\psoc4hvXXXk\src\examples\adc\dual

Each block configuration:

ACHAN 0/DCHAN0 configuration - current sensor

Continuous sampling mode

Primary channel

Stage 1 decimation filter: Sync 3, DR = 64

Stage 2 decimation filter: Sync 1, DR2 = 6

Sampling shunt resistor across RSL and RSH

Zero channel select delay (since this DCHAN has a dedicated ACHAN)

15-tap FIR filter

Accumulate four samples

ACHAN 1/DCHAN1 configuration - voltage sensor

Continuous sampling mode

Primary channel

Stage 1 decimation filter: Sync 3, DR = 64

Stage 2 decimation filter: Sync 2, DR2 = 6

Sampling the high-voltage divider between VSENSE and GND

Zero channel select delay (since this DCHAN has a dedicated ACHAN)

15-tap FIR filter

Unity gain

shows the PACSS sequencer timing for dual convert design.

Figure 10. PACSS sequencer timing of dual convert design

Note: The ADC is sampling much faster than the UART output so not all sampled results will be transmitted. This applies to all of the examples.

shows the flow chart for dual convert design, and

Code Listing 1

shows the code example of main function.

Note: User should compare the code example with the flowchart, and learn how to use the PACSS functions. You cannot copy/paste the code and expect it to work. This applies to all code examples provided in this document.

Figure 11. Flowchart of dual convert design

Code Listing 1 Main function of dual convert design

001 int main(void)

002 {

003 cy_en_adc_error_t error = CY_ADC_ERROR;

004 int32_t currentChannelResult = 0;

005 int32_t voltageChannelResult = 0;

006 float32_t millivoltsAcrossShunt = 0.0;

007 float32_t batteryVoltage = 0.0;

008

009 SystemInit();

010

011 /* Enable DCHAN0 Interrrupt */

012 Cy_SysInt_EnableIRQ(CY_PACSS_ADC_DCHAN0_IRQN);

013 Cy_SysInt_SetVector(CY_PACSS_ADC_DCHAN0_IRQN, Adc_Dchan0_IntrISR);

014 Cy_SysInt_ClearPendingIRQ(CY_PACSS_ADC_DCHAN0_IRQN);

015 Cy_Adc_SetInterruptMask(PACSS_DCHAN0, CY_ADC_DCHAN_INTERRUPT_DATA_VAL);

016

017 /* Enable DCHAN1 Interrrupt */

018 Cy_SysInt_EnableIRQ(CY_PACSS_ADC_DCHAN1_IRQN);

019 Cy_SysInt_SetVector(CY_PACSS_ADC_DCHAN1_IRQN, Adc_Dchan1_IntrISR);

020 Cy_SysInt_ClearPendingIRQ(CY_PACSS_ADC_DCHAN1_IRQN);

021 Cy_Adc_SetInterruptMask(PACSS_DCHAN1, CY_ADC_DCHAN_INTERRUPT_DATA_VAL);

022

023 /* Enable global interrupts. */

024 __enable_irq();

025

026 Example_UartInit();

027

028 /* Divide 24 MHz HF clock to get 3 MHz PACSS Clock */

029 Cy_SysClk_PeriphAssignDivider(CY_PACSS_ADC_PCLK, CY_SYSCLK_DIV_16_BIT,

030 PACSS_DSM_CLK_PERI_DIVIDER_NUM);

031 Cy_SysClk_PeriphSetDivider(CY_SYSCLK_DIV_16_BIT,

032 PACSS_DSM_CLK_PERI_DIVIDER_NUM,

033 CY_ADC_PERIPHERAL_CLOCK_DIVIDE_3 MHz);

034

035 /* Enable peripheral divider */

036 Cy_SysClk_PeriphEnableDivider(CY_SYSCLK_DIV_16_BIT,

037 PACSS_DSM_CLK_PERI_DIVIDER_NUM);

038

039 /* Set the pump clock source to the IMO */

040 Cy_SysClk_SetSourcePumpClk(CY_SYSCLK_PUMP_SEL_IMO);

041

042 /* Enable the HV Divider on VSENSE */

043 Cy_Hvss_Rvid_EnableVS0();

044

045 /***************************************************************************

046 * Configure the PACSS

047 **************************************************************************/

048 Cy_Adc_EnableSequencer(PACSS_MMIO);

049 Cy_Adc_EnableReference(PACSS_MMIO);

050

051 /* Sequencer must be enabled 1000us before enabling any analog channels to

052 allow the reference currents to settle */

053 Cy_SysLib_DelayUs(CY_ADC_REFERENCE_DELAY_US);

054

055 /* ACHAN0 / DCHAN0 config */

056 error = Cy_Adc_InitAchan(PACSS_ACHAN0, &cy_stc_adc_achan0_config);

057 CY_ASSERT(CY_ADC_ERROR_NONE == error);

058 error = Cy_Adc_InitAchanChannelChopping(PACSS_ACHAN0,

059 &cy_stc_current_channel_chopping_config);

060 CY_ASSERT(CY_ADC_ERROR_NONE == error);

061 Cy_Adc_EnableAchan(PACSS_ACHAN0);

062 error = Cy_Adc_InitDchan(PACSS_DCHAN0, &cy_stc_adc_dchan0_config);

063 CY_ASSERT(CY_ADC_ERROR_NONE == error);

064 Cy_Adc_EnableDchan(PACSS_DCHAN0);

065

066 /* ACHAN1 / DCHAN1 config */

067 error = Cy_Adc_InitAchan(PACSS_ACHAN1, &cy_stc_adc_achan1_config);

068 CY_ASSERT(CY_ADC_ERROR_NONE == error);

069 error = Cy_Adc_InitAchanChannelChopping(PACSS_ACHAN1,

&cy_stc_voltage_channel_chopping_config);

070 CY_ASSERT(CY_ADC_ERROR_NONE == error);

071 Cy_Adc_EnableAchan(PACSS_ACHAN1);

072 error = Cy_Adc_InitDchan(PACSS_DCHAN1, &cy_stc_adc_dchan1_config);

073 CY_ASSERT(CY_ADC_ERROR_NONE == error);

074 Cy_Adc_EnableDchan(PACSS_DCHAN1);

075

076 /* Analog channel must be enabled for 3us before starting conversions */

077 Cy_SysLib_DelayUs(CY_ADC_ACHAN_DELAY_US);

078

079 /* AGC */

080 Cy_Adc_InitAgc(PACSS_MMIO, &cy_stc_adc_agc_config);

081 Cy_Adc_EnableAgc(PACSS_MMIO);

082

083 /* Calibrate the ADC channels */

084 Cy_Adc_CalibrateOffsetScalar(PACSS_DCHAN0);

085 Cy_Adc_CalibrateOffsetScalar(PACSS_DCHAN1);

086 Adc_Calibrate();

087

088 /* Start the conversion process */

089 Cy_Adc_StartConversion(PACSS_MMIO);

090

091 /* Opening UART Comment */

092 Example_UartPrintf("\r\nADC Dual Example\r\n");

093

094 /* Settle the FIR filters */

095 uint32_t voltageFilterSettle = 0;

096 uint32_t currentFilterSettle = 0;

097 while ((voltageFilterSettle < CY_ADC_FIR_NUM_TAPS) || (currentFilterSettle <

CY_ADC_FIR_NUM_TAPS))

098 {

099 if(g_voltageDataValid)

100 {

101 g_voltageDataValid = false;

102 voltageFilterSettle++;

103 }

104 if(g_currentDataValid)

105 {

106 g_currentDataValid = false;

107 currentFilterSettle++;

108 }

109 }

110

111 while (1)

112 {

113 if(g_currentDataValid)

114 {

115 g_currentDataValid = false;

116

117 Cy_Adc_GetResult(PACSS_DCHAN0, ¤tChannelResult);

118 millivoltsAcrossShunt = Cy_Adc_CountsToMillivolts(currentChannelResult,

119 CY_ADC_CURRENT_CHANNEL, CY_ADC_SAMPLE_RATE_8KSPS, CY_ADC_HBPGR_VOLTAGE);

120

121 Example_UartPrintf("Current (mV): %.2f\r\n", millivoltsAcrossShunt);

122 }

123

124 if(g_voltageDataValid)

125 {

126 g_voltageDataValid = false;

127

128 Cy_Adc_GetResult(PACSS_DCHAN1, &voltageChannelResult);

129 batteryVoltage = Cy_Adc_CountsToVolts(voltageChannelResult,

130 CY_ADC_VOLTAGE_CHANNEL,

131 CY_ADC_SAMPLE_RATE_8KSPS,

132 CY_ADC_HBPGR_VOLTAGE);

133

134 batteryVoltage = batteryVoltage * HVDIV_ATTENUATION;

135 Example_UartPrintf("Voltage (V): %.2f\r\n", batteryVoltage);

136 }

137 }

138 }

Triple convert design (current/voltage/temperature)

This example uses same configuration of current and voltage channels from the 'dual' example. Additionally, a third channel measures the external temperature at a 20-millisecond interval triggered by a PWM. The temperature measurement is a secondary measurement and it shares ACHAN1 with the battery voltage (VSENSE) measurement. The results display in millivolts over the UART connection. The code example is located in SDL path of:

C:/<user path>

PSoC_Sample_Driver_Library_x.x.x\psoc4hvXXXk\src\examples\adc\triple

Each block configuration:

ACHAN 0/DCHAN0 configuration - current sensor

Same as dual convert design

ACHAN 1/DCHAN1 configuration - voltage sensor

Same as dual convert design

ACHAN 1/DCHAN2 configuration - external temperature sensor

Single shot sampling mode

Secondary channel

Stage 1 decimation filter: Sync 3, DR = 64

Stage 2 decimation filter: Sync 2, DR2 = 1

Sampling the external temperature sensor (VTEMP and VTEMP_RET)

17 clock channel select delay to allow ADC to settle between input switching

VREFH of VDDA/3 and VREFL to VTEMP_RET to keep the measurement ratio-metric since the source for the thermistor circuit is VDDA

Unity gain

shows the PACSS sequencer timing for triple convert design.

Figure 12. PACSS sequencer timing of triple convert design

shows the flow chart for triple convert design, and

Code Listing 2

shows the code example of main function.

Figure 13. Flowchart of triple convert design

Code Listing 2 Main function of triple convert design

001 int main(void)

002 {

003 cy_en_adc_error_t error = CY_ADC_ERROR;

004 int32_t currentChannelResult = 0;

005 int32_t voltageChannelResult = 1;

006 int32_t temperatureChannelResult = 1;

007 float32_t millivoltsAcrossShunt = 0.0;

008 float32_t millivoltsTempSensor = 0.0;

009 float32_t batteryVoltage = 0.0;

010

011 ~~~~~~ omitted (same as dual) ~~~~~~

012

013 /* Enable DCHAN2 Interrrupt */

014 Cy_SysInt_EnableIRQ(CY_PACSS_ADC_DCHAN2_IRQN);

015 Cy_SysInt_SetVector(CY_PACSS_ADC_DCHAN2_IRQN, Adc_Dchan2_IntrISR);

016 Cy_SysInt_ClearPendingIRQ(CY_PACSS_ADC_DCHAN2_IRQN);

017 Cy_Adc_SetInterruptMask(PACSS_DCHAN2, CY_ADC_DCHAN_INTERRUPT_DATA_VAL);

018

019 __enable_irq(); /* Enable global interrupts. */

020

021 /* Initialize GPIOs for measuring temperature */

022 External_TempSensorInit();

023

024 ~~~~~~ omitted (same as dual) ~~~~~~

025

026 /*--------------------------------*/

027 /* Clock Configuration for TCPWM */

028 /*--------------------------------*/

029

030 /* Assign a programmable divider for TCPWM_CNT0 */

031 Cy_SysClk_PeriphAssignDivider(PCLK_TCPWM_CLOCKSx_COUNTER,

032 (cy_en_divider_types_t)CY_SYSCLK_DIV_16_BIT,

033 TCPWM_CNT_CLK_PERI_DIVIDER_NUM);

034 Cy_SysClk_PeriphSetDivider((cy_en_divider_types_t)CY_SYSCLK_DIV_16_BIT,

035 TCPWM_CNT_CLK_PERI_DIVIDER_NUM, TCPWM_CLOCK_16DIV);

036 Cy_SysClk_PeriphEnableDivider((cy_en_divider_types_t)CY_SYSCLK_DIV_16_BIT,

037 TCPWM_CNT_CLK_PERI_DIVIDER_NUM);

038

039 /* Set the pump clock source to the IMO */

040 Cy_SysClk_SetSourcePumpClk(CY_SYSCLK_PUMP_SEL_IMO);

041

042 // Enable the HV Divider on VSENSE

043 Cy_Hvss_Rvid_EnableVS0();

044

045 /* Assign PWM compare match to ADC Trigger 0 */

046 Cy_TrigMux_Connect(TRIG2_IN_TCPWM_TR_COMPARE_MATCH0, TRIG2_OUT_PACSS_TR_START0);

047

048 /***************************************************************************

049 * Configure the PACSS

050 **************************************************************************/

051

052 ~~~~~~ omitted (same as dual) ~~~~~~

053

054 // Temperature Sensor

055 Cy_Adc_EnableTemperature(PACSS_MMIO);

056

057 ~~~~~~ omitted (same as dual) ~~~~~~

058

059 error = Cy_Adc_InitDchan(PACSS_DCHAN2, &cy_stc_adc_dchan2_config);

060 CY_ASSERT(CY_ADC_ERROR_NONE == error);

061 Cy_Adc_EnableDchan(PACSS_DCHAN2);

062

063 ~~~~~~ omitted (same as dual) ~~~~~~

064

065 Cy_Adc_CalibrateOffsetScalar(PACSS_DCHAN2);

066

067 ~~~~~~ omitted (same as dual) ~~~~~~

068

069 /* Initialize TCPWM_CNTx_COUNTER in PWM Mode & Enable */

070 Cy_Tcpwm_DisableCounter(TCPWM_CNTx_COUNTER);

071 Cy_Tcpwm_Pwm_Init(TCPWM_CNTx_COUNTER, &cy_stc_pwm_config);

072 Cy_Tcpwm_EnableCounter(TCPWM_CNTx_COUNTER);

073 Cy_Tcpwm_EnableCounterCommand(TCPWM_CNTx_COUNTER, CY_TCPWM_CMD_COUNTER_START);

074

075 ~~~~~~ omitted (same as dual) ~~~~~~

076

077 while (1)

078 {

079

080 ~~~~~~ omitted (same as dual) ~~~~~~

081

082 if (g_temperatureDataValid)

083 {

084 g_temperatureDataValid = false;

085

086 Cy_Adc_GetResult(PACSS_DCHAN2, &temperatureChannelResult);

087 millivoltsTempSensor = Cy_Adc_CountsToMillivolts(

088 temperatureChannelResult,

089 CY_ADC_DIAGNOSTIC_CHANNEL,

090 CY_ADC_SAMPLE_RATE_48KSPS,

091 CY_ADC_VDDA_BY_3_VOLTAGE);

092

093 Example_UartPrintf("Diagnostic, Temp Sensor Voltage (mV): %.2f\r\n", millivoltsTempSensor);

094 }

095 }

096 }

Multi convert design (current/voltage/multi data)

This example uses the same configuration of current and voltage channels from the 'dual' and 'triple' examples except that the primary channels run at 2 ksps instead of 8 ksps. Also, instead of just measuring temperature, the third channel cycles through the following measurements:

External temperature

Internal die temperature: Resistor (measure twice)

Internal die temperature: Bipolar transistor (measure twice)

VDIAG vs ground

RSH2/RSL2

Shunt disconnection detect (measure twice)

SRSS bandgap reference vs Ground

High-precision bandgap reference (HPBGR) vs Ground

Note: Die temperature measurement and shunt disconnection detection both require two ADC results.

All results display over the UART connection. The code example is located in SDL path of:

C:/<user path>

PSoC_Sample_Driver_Library_x.x.x\psoc4hvXXXk\src\examples\adc\rev_b\multi

Each block configuration:

ACHAN 0/DCHAN0 configuration - current sensor

Same as dual convert design except DR and DR2 values

Stage 1 decimation filter: Sync 3, DR = 128

Stage 2 decimation filter: Sync 2, DR2 = 12

ACHAN 1/DCHAN1 configuration - Voltage Sensor

Same as dual convert design except DR and DR2 values

Stage 1 decimation filter: Sync 3, DR = 128

Stage 2 decimation filter: Sync 2, DR2 = 12

ACHAN 1/DCHAN2 configuration - Multiple diagnostic inputs

Single shot sampling mode

Secondary channel

Stage 1 decimation filter: Sync 3, DR = 64

Stage 2 decimation filter: Sync 2, DR2 = 1

Sampling the multiple diagnostic inputs

17 clock channel select delay to allow ADC to settle between input switching

shows the PACSS sequencer timing for multi convert design.

Figure 14. PACSS sequencer timing of multi convert design

shows the flow chart for multi convert design, and

Code Listing 3

shows the code example of main function.

Figure 15. Flowchart of multi convert design

Code Listing 3 Main function of multi convert design

001 int main(void)

002 {

003 cy_en_adc_error_t error = CY_ADC_ERROR;

004 int32_t currentChannelResult = 0;

005 int32_t voltageChannelResult = 1;

006 int32_t diagnosticChannelResult = 1;

007 float32_t millivoltsAcrossShunt = 0.0;

008 float32_t batteryvoltage = 0.0;

009 int32_t diagnosticState = 0;

010 int32_t totalDiagnostic = 0;

011 adc_diagnostic_config_t diagnosticConfigs[] = {

012 DIAGNOSTIC_CHANNEL_CONFIG_EXTERNAL_TEMP,

013 DIAGNOSTIC_CHANNEL_CONFIG_RESISTOR_ONE,

014 DIAGNOSTIC_CHANNEL_CONFIG_RESISTOR_UNIT,

015 DIAGNOSTIC_CHANNEL_CONFIG_DIE_TEMP_ONE,

016 DIAGNOSTIC_CHANNEL_CONFIG_DIE_TEMP_UNIT,

017 DIAGNOSTIC_CHANNEL_CONFIG_VDIAG,

018 DIAGNOSTIC_CHANNEL_CONFIG_RSH2,

019 DIAGNOSTIC_CHANNEL_CONFIG_RS_OPEN_PULLUP,

020 DIAGNOSTIC_CHANNEL_CONFIG_RS_OPEN_SHUNT,

021 DIAGNOSTIC_CHANNEL_CONFIG_SRSS_REF,

022 DIAGNOSTIC_CHANNEL_CONFIG_HPBGR_REF

023 };

024

025 g_previousTemperature = CY_ADC_ROOM_TEMPERATURE_FIXED;

026 g_nextTemperature = CY_ADC_ROOM_TEMPERATURE_FIXED;

027

028 totalDiagnostic = sizeof(diagnosticConfigs) / sizeof(diagnosticConfigs[0]);

029

030 ~~~~~~ omitted (same as triple) ~~~~~~

031

032 /* Initialize the die temp configurations */

033 Cy_Adc_InitializeDieTempConfigs(

034 &cy_stc_die_temp_one_config,

035 &cy_stc_die_temp_unit_config,

036 CY_ADC_DIE_TEMP_PRIMARY);

037

038 ~~~~~~ omitted (same as triple) ~~~~~~

039

040 /* Enable die temperature sensor */

041 Cy_Adc_EnableTemperature(PACSS_MMIO);

042

043 ~~~~~~ omitted (same as triple) ~~~~~~

044

045 while (1)

046 {

047

048 ~~~~~~ omitted (same as triple) ~~~~~~

049

050 if (g_diagnosticDataValid)

051 {

052 g_diagnosticDataValid = false;

053 Cy_Adc_GetResult(PACSS_DCHAN2, &diagnosticChannelResult);

054 Adc_DiagnosticHandler(diagnosticConfigs[diagnosticState],

055 diagnosticChannelResult);

056

057 if (diagnosticState == totalDiagnostic)

058 {

059 diagnosticState = 0;

060 }

061 else

062 {

063 diagnosticState++;

064 }

065

066 Adc_SetChannelConfig(PACSS_DCHAN2,

067 diagnosticConfigs[diagnosticState]);

068

069 /* Initiate the second Die Temp measurement */

070 if (DIAGNOSTIC_CHANNEL_CONFIG_DIE_TEMP_UNIT == diagnosticState)

071 {

072 Cy_Adc_PacssMmio_StartSecondaryConversion(PACSS_MMIO);

073 }

074 }

075

076 /* Re-calibrate if temperature changes by 5C */

077 if (g_nextTemperature > (g_previousTemperature + CY_ADC_5_DEGREES_C_FIXED)

078 || (g_nextTemperature < (g_previousTemperature -

CY_ADC_5_DEGREES_C_FIXED)))

079 {

080 g_previousTemperature = g_nextTemperature;

081

082 Example_UartPrintf("Re-calibrating\r\n");

083 Adc_Calibrate(g_nextTemperature);

084 }

085 }

086 }

087

088 /******************************************************************************

089 * Adc_DiagnosticHandler

090 *******************************************************************************

091 * Call the handler function for the specified diagnostic channel measurement:

092 * - External Temperature

093 * - Internal Die Temperature

094 * - VDIAG vs Ground

095 * - RSH2/RSL2

096 * - Shunt disconnection detect

097 * - SRSS VREF vs Ground

098 * - HPBGR VREF vs Ground

099 ******************************************************************************/

100 void Adc_DiagnosticHandler(adc_diagnostic_config_t state, int32_t result)

101 {

102 static int32_t currentOne = 0;

103 static int32_t dieTempOne = 0;

104 static int32_t rshPullup = 0;

105 static float currentRatio = 0.0;

106

107 switch(state)

108 {

109 case DIAGNOSTIC_CHANNEL_CONFIG_EXTERNAL_TEMP:

110 Adc_ExternalTempSensorHandler(result);

111 break;

112

113 case DIAGNOSTIC_CHANNEL_CONFIG_RESISTOR_ONE:

114 currentOne = result;

115 break;

116

117 case DIAGNOSTIC_CHANNEL_CONFIG_RESISTOR_UNIT:

118 Adc_CurrentRatioHandler(¤tRatio, currentOne, result);

119 break;

120

121 case DIAGNOSTIC_CHANNEL_CONFIG_DIE_TEMP_ONE:

122 dieTempOne = result;

123 break;

124

125 case DIAGNOSTIC_CHANNEL_CONFIG_DIE_TEMP_UNIT:

126 Adc_DieTempHandler(result - dieTempOne, currentRatio);

127 break;

128

129 case DIAGNOSTIC_CHANNEL_CONFIG_VDIAG:

130 Adc_VdiagHandler(result);

131 break;

132

133 case DIAGNOSTIC_CHANNEL_CONFIG_RSH2:

134 Adc_Rsh2Handler(result);

135 break;

136

137 case DIAGNOSTIC_CHANNEL_CONFIG_RS_OPEN_PULLUP:

138 rshPullup = result;

139 break;

140

141 case DIAGNOSTIC_CHANNEL_CONFIG_RS_OPEN_SHUNT:

142 Adc_RshOpenhandler(rshPullup, result);

143 break;

144

145 case DIAGNOSTIC_CHANNEL_CONFIG_SRSS_REF:

146 Adc_VrefSrssHandler(result);

147 break;

148

149 case DIAGNOSTIC_CHANNEL_CONFIG_HPBGR_REF:

150 Adc_VrefHpbgrHandler(result);

151 break;

152

153 default:

154 Adc_SetChannelConfig(PACSS_DCHAN2, DIAGNOSTIC_CHANNEL_CONFIG_EXTERNAL_TEMP);

155 break;

156 }

157 }

PACSS calibration

The digital channels allow adjustments to offset and gain to correct cumulative errors in the analog circuits. The offset and gain are calibrated during test at multiple temperatures and for multiple configurations. Offset and gain calibration data is stored in SFLASH memory such as SFLASH_PACSS_XXXX registers. Customer software is responsible for reading the correct SFLASH data for the desired configuration, interpolating that data between temperatures, and loading the data into hardware registers. This chapter describes the PACSS calibration method using SDL example.

The PACSS calibration is divided into the following sections:

Calibration drivers

Code example

Channel OFFSET and GAIN calibration

The following sections explain the details API and code examples for PACSS calibration.

Calibration drivers

lists and describes the interface to the PACSS calibration function. The calibration drivers of PACSS are located in SDL path of:

C:/<user path>\ PSoC_Sample_Driver_Library_x.x.x\psoc4hvXXXk\src\mw\adc\rev_b

Function | Description |

|---|---|

cy_adc_calibrate.c | |

Cy_Adc_CalibrateAgcGainLevel() | Loads gain and offset correction values from the supervisory flash |

Cy_Adc_CalibrateAchan0_2TempTrim() | Loads gain and offset correction values from the supervisory flash |

Cy_Adc_CalibrateAchan1_2TempTrim() | Loads gain and offset correction values from the supervisory flash |

Cy_Adc_CalibrateAchan1_3TempTrim() | Loads gain and offset correction values from the supervisory flash |

Cy_Adc_GetGcorOcorAchan0_2TempTrim() | Retrieves gain and offset correction values from the supervisory flash |

Cy_Adc_GetGcorOcorAchan1_2TempTrim() | Retrieves gain and offset correction values from the supervisory flash |

Cy_Adc_GetGcorOcorAchan1_3TempTrim() | Retrieves gain and offset correction values from the supervisory flash |

Cy_Adc_CalibrateOffsetScalar() | Loads offset correction scalar value from the supervisory flash |

cy_adc_counts_to_volts.c (Auxiliary functions) | |

Cy_Adc_CountsToVolts() | Converts the input from raw ADC counts to volts |

Cy_Adc_CountsToMillivolts() | Converts the input from raw ADC counts to millivolts |

Code example

Channel OFFSET and GAIN calibration

The calibration data requires analog channel usage of ACHAN0: Current and ACHAN1: Voltage and diagnostic. See "21.2.7.1 Channel OFFSET and GAIN calibration" in the architecture TRM

[5]

for more details.

Note: The offset correction (OCOR) values stored in SFlash are determined using specific digital channel (DCHAN) configurations. The OCOR is applied at the output of the decimator right shift (DEC_SHIFTR). Any changes to the DCHAN that affect the scale of this output require a corresponding change to either the DCHAN settings or the OCOR value to align them back to the same scale. See offset correction values alignment section in the architecture TRM for more details.

This example uses the multi convert design, and focuses on the calibration function.

Figure 16

shows the flowchart for channel OFFSET and GAIN calibration, and

Code Listing 4

shows the code example of the main function.

Figure 16. Flowchart of channel OFFSET and GAIN calibration

Code Listing 4 Code example of channel OFFSET and GAIN calibration

001 int main(void)

002 {

003

004 ~~~~~~ omitted ~~~~~~

005

006 /* Calibrate the ADC channels */

007 Cy_Adc_CalibrateOffsetScalar(PACSS_DCHAN0);

008 Cy_Adc_CalibrateOffsetScalar(PACSS_DCHAN1);

009 Cy_Adc_CalibrateOffsetScalar(PACSS_DCHAN2);

010 Adc_Calibrate(g_previousTemperature);

011

012 /* Start the conversion process */

013 Cy_Adc_StartConversion(PACSS_MMIO);

014

015 ~~~~~~ omitted ~~~~~~

016

017 while (1)

018 {

019

020 ~~~~~~ omitted ~~~~~~

021

022 // Re-calibrate if temperature changes by 5C

023 if (g_nextTemperature > ( g_previousTemperature + CY_ADC_5_DEGREES_C_FIXED)

024 || (g_nextTemperature < ( g_previousTemperature -

CY_ADC_5_DEGREES_C_FIXED)))

025 {

026 g_previousTemperature = g_nextTemperature;

027

028 //Re-calibrate

029 Example_UartPrintf("Re-calibrating\r\n");

030 Adc_Calibrate(g_nextTemperature);

031 }

032 }

033 }

034

035 /******************************************************************************

036 * Adc_Calibrate

037 *******************************************************************************

038 * Calibrate the AGC, the VSENSE, and Diagnostic channels to the temperature

039 * \param temperature The temperature in fixed point 12.20 format

040 ******************************************************************************/

041 void Adc_Calibrate(int32_t temperature)

042 {

043 uint16_t gcor;

044 int16_t ocor;

045

046 Cy_Adc_CalibrateAchan1_3TempTrim(

047 PACSS_DCHAN1,

048 CY_ADC_ACHAN1_3TEMP_VSENSE_16,

049 temperature);

050 Cy_Adc_CalibrateAchan1_2TempTrim(

051 PACSS_DCHAN2,

052 CY_ADC_ACHAN1_2TEMP_GAIN_1X,

053 temperature);

054

055 /* Calibrate the AGC Gain levels */

056 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 0, temperature,

057 CY_ADC_ACHAN0_2TEMP_GAIN_2X);

058 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 1, temperature,

059 CY_ADC_ACHAN0_2TEMP_GAIN_4X);

060 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 2, temperature,

061 CY_ADC_ACHAN0_2TEMP_GAIN_8X);

062 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 3, temperature,

063 CY_ADC_ACHAN0_2TEMP_GAIN_16X);

064 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 4, temperature,

065 CY_ADC_ACHAN0_2TEMP_GAIN_32X);

066 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 5, temperature,

067 CY_ADC_ACHAN0_2TEMP_GAIN_64X);

068 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 6, temperature,

069 CY_ADC_ACHAN0_2TEMP_GAIN_128X);

070 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 7, temperature,

071 CY_ADC_ACHAN0_2TEMP_GAIN_256X);

072 Cy_Adc_CalibrateAgcGainLevel(PACSS_MMIO, 8, temperature,

073 CY_ADC_ACHAN0_2TEMP_GAIN_512X);

074

075 /* Calibrate the current channel for static gain, AGC disabled

076 This assumes the static gain comes from the cy_stc_adc_gain_level_config

077 array which includes the left shift to keep the number scale the same*/

078 Cy_Adc_GetGcorOcorAchan0_2TempTrim(&gcor, &ocor,

079 CY_ADC_ACHAN0_2TEMP_GAIN_512X, temperature);

080 Cy_Adc_DchanPostProcessing_SetGainCorrection(PACSS_DCHAN0, gcor);

081 Cy_Adc_DchanPostProcessing_SetOffsetCorrection(PACSS_DCHAN0, ocor);

082 }

PACSS diagnostic features

The PACSS diagnostic features is divided into the following sections:

Diagnostic drivers

Code example

On-die temperature calculation

Shunt resistor open detection of RSx pins

The following sections explain the details API and code examples for PACSS diagnostic features.

Diagnostic drivers

lists and describes the interface to PACSS diagnostic function. The Diagnostic drivers of PACSS are located in the SDL path of:

C:/<user path>\ PSoC_Sample_Driver_Library_x.x.x\psoc4hvXXXk\src\mw\adc\rev_b

Function | Description |

|---|---|

cy_adc_die_temp.c | |

Cy_Adc_GetDieTempFromDelta() | Converts the delta between two die temp measurements to degrees. Centigrade in fixed point 12.20 format |

Cy_Adc_InitializeDieTempConfigs() | Initializes the two configurations used for temperature measurement with factory settings |

Cy_Adc_NormalizeDelta | Normalizes the delta VBE measurement to the ratio of the current sources |

cy_adc_rs_open.c | |

Cy_Adc_GetPullupResistance() | Returns the linearly interpolated resistance of the pull-up resistor |

Cy_Adc_IsRsOpen() | Uses samples of the shunt resistor and pull-up resistor to determine if the shunt resistor is disconnected (open) |

Code example

On-die temperature calculation

On-die temperature measurements are made with an internal temperature sensor by measuring bipolar VBE at different current densities and calculating temperature. Two independent current references are used for diagnosis and redundancy. In addition to temperature, die stress also causes VBE shifts but NPN and PNP bipolars respond differently to stress; therefore, arrays of both transistor types are included. See "21.2.6.2 On-die temperature sensor" in the architecture TRM for more details.

On-die temperature measurements convert the delta between two die temp measurements to degrees (celsius in fixed point 12.20 format). The following is formula of the internal temperature calculation. See "21.2.7.2 Internal temperature calculation" in the architecture TRM

[5]

.

T = α2 * x2/234 + α1 * x/29 + α0 * 214

Where:

x = dVBE + dVBE * (A * ratio + B)

dVBE = ADC(UNIT) - ADC(1) with 29 bit signed result

ratio = ADC(UNIT) / ADC(1) with LOAD_MODE set to “resistor”

A = -0.0534, B = 0.4804

where (A * ratio + B) is a linear approximation of LN(9)/LN(ratio).

ADC(UNIT) is the measurement with UNIT_MODE and IREF_BIPOLAR_UNIT_MASK applied.

a2, a1, and a0 coefficients are read from either SFlash (two circuits, primary and alternate, are available for diagnostic)

shows the flow chart for internal temperature calculation, and

Code Listing 5

shows the code example of main function.

Figure 17. Flowchart of internal temperature calculation

Code Listing 5 Code example of internal temperature calculation

001 int main(void)

002 {

003 cy_en_adc_error_t error = CY_ADC_ERROR;

004 int32_t dieTempOneCounts = 0;

005 int32_t dieTempUnitCounts = 0;

006 int32_t deltaVbe = 0;

007 int32_t deltaVbeNormalized = 0;

008 int32_t tempFixed = 0;

009 float32_t tempFloat = 0.0;

010 float32_t currentRatio = 0.0;

011

012 ~~~~~~ omitted ~~~~~~

013

014 /* Initialize the die temp configurations */

015 Cy_Adc_InitializeDieTempConfigs(&cy_stc_die_temp_one_config,

016 &cy_stc_die_temp_unit_config, CY_ADC_DIE_TEMP_PRIMARY);

017

018 Cy_Adc_InitTemperature(PACSS_MMIO, &cy_stc_die_temp_one_config);

019 Cy_Adc_EnableTemperature(PACSS_MMIO);

020

021 /* Get the ratio of the resistor measurements to normalize the results */

022 Cy_Adc_InitTemperature(PACSS_MMIO, &cy_stc_die_temp_one_config);

023 Cy_Adc_PacssMmioTemperature_SetLoadMode(PACSS_MMIO,

024 CY_ADC_TEMPERATURE_LOAD_MODE_RESISTOR);

025 dieTempOneCounts = Adc_GetConversion();

026

027 /* Configure for the unit measurement */

028 Cy_Adc_InitTemperature(PACSS_MMIO, &cy_stc_die_temp_unit_config);

029 Cy_Adc_PacssMmioTemperature_SetLoadMode(PACSS_MMIO,

030 CY_ADC_TEMPERATURE_LOAD_MODE_RESISTOR);

031 dieTempUnitCounts = Adc_GetConversion();

032

033 currentRatio = (float32_t) dieTempUnitCounts / (float32_t) dieTempOneCounts;

034

035 ~~~~~~ omitted ~~~~~~

036

037 while (1)

038 {

039 /* Configure for the first measurement */

040 Cy_Adc_InitTemperature(PACSS_MMIO, &cy_stc_die_temp_one_config);

041 dieTempOneCounts = Adc_GetConversion();

042

043 /* Configure for the unit measurement */

044 Cy_Adc_InitTemperature(PACSS_MMIO, &cy_stc_die_temp_unit_config);

045 dieTempUnitCounts = Adc_GetConversion();

046

047 deltaVbe = dieTempUnitCounts - dieTempOneCounts;

048 deltaVbe = deltaVbe << ADC_GET_DIE_TEMP_SHIFT;

049 Example_UartPrintf("Diagnostic, Delta Vbe (counts): %d\r\n", deltaVbe);

050 Cy_Adc_NormalizeDelta(&deltaVbeNormalized, deltaVbe, currentRatio);

051 Example_UartPrintf("Diagnostic, Delta Vbe (counts): %d\r\n",

052 deltaVbeNormalized);

053

054 Cy_Adc_GetDieTempFromDelta(&tempFixed, deltaVbeNormalized,

055 CY_ADC_DIE_TEMP_PRIMARY);

056 tempFloat = (float32_t) tempFixed / ADC_FIXED_TO_FLOAT;

057 Example_UartPrintf("Diagnostic, Temp (C): %.02f\r\n", tempFloat); }

058 }

059

060 /*******************************************************************************

061 * Function Name: Cy_Adc_GetDieTempFromDelta

062 ****************************************************************************//**

063 * \brief Converts the delta between two die temp measurements to degrees

064 * Centigrade in fixed point 12.20 format.

065 *

066 * Uses the formula (a2 * x^2 * 2^-34 + a1 * x * 2^-9 + a0 * 2^14)/2^20

067 * where x = Delta ADC = ADC(UNIT) - ADC(1)

068 *

069 * The division by 2^20 is not performed, it is symbolic of the fixed

070 * point 12.20 format of the result.

071 *

072 * \param delta 32-bit delta between the two die temp measurements

073 * \param result Pointer for the conversion result in fixed point 12.20 format

074 * \param setup Selects the primary or alternate temperature measurement

075 * coefficients stored in sflash

076 *

077 * \return #CY_ADC_ERROR_NONE if no errors occur

078 * \return #CY_ADC_ERROR_BAD_PARAM if `delta` is invalid

079 * \return #CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL if `result` is NULL

080 *******************************************************************************/

081 cy_en_adc_error_t Cy_Adc_GetDieTempFromDelta(int32_t *result, int32_t delta,

082 cy_en_adc_die_temp_setup_t setup)

083 {

084 cy_en_adc_error_t status = CY_ADC_ERROR;

085 int16_t a2 = 0;

086 int16_t a1 = 0;

087 int16_t a0 = 0;

088 int64_t sqrdTerm;

089 int64_t linearTerm;

090 int64_t offset;

091

092 if (NULL == result)

093 {

094 status = CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL;

095 }

096 else

097 {

098 if (CY_ADC_DIE_TEMP_PRIMARY == setup)

099 {

100 a2 = SFLASH->unPACSS_DIAG_TEMP_P_CAL_A2.u16Register;

101 a1 = SFLASH->unPACSS_DIAG_TEMP_P_CAL_A1.u16Register;

102 a0 = SFLASH->unPACSS_DIAG_TEMP_P_CAL_A0.u16Register;

103 }

104 else

105 {

106 a2 = SFLASH->unPACSS_DIAG_TEMP_A_CAL_A2.u16Register;

107 a1 = SFLASH->unPACSS_DIAG_TEMP_A_CAL_A1.u16Register;

108 a0 = SFLASH->unPACSS_DIAG_TEMP_A_CAL_A0.u16Register;

109 }

110

111 // a2 * x^2 * 2^-34

112 sqrdTerm = delta;

113 sqrdTerm = sqrdTerm * sqrdTerm;

114 sqrdTerm = sqrdTerm >> DIE_TEMP_SQUARED_TERM_SHIFT;

115 sqrdTerm = sqrdTerm * a2;

116

117 // a1 * x * 2^-9

118 linearTerm = delta;

119 linearTerm = linearTerm >> DIE_TEMP_LINEAR_TERM_SHIFT;

120 linearTerm = linearTerm * a1;

121

122 // a0 * 2^14

123 offset = a0 << DIE_TEMP_OFFSET_TERM_SHIFT;

124

125 *result = sqrdTerm + linearTerm + offset;

126

127 status = CY_ADC_ERROR_NONE;

128 }

129

130 return status;

131 }

Shunt resistor open detection of RSx pins

The current measurement channel detects disconnect shunt connections by switching internal pull-up resistors to the shunt pins. If the resistance between the RSHx or RSLx to ground is more than 1000 Ω, an open pin fault can be detected.

Detection criteria:

Vadc_th must be defined to separate "good" (lower voltage) from "open" (higher voltage)

Rdet < 250 Ω should always return "good" status

Rdet > 1000 Ω should always return "open" status

This example uses the shunt resistor and pull-up resistor to determine if the shunt resistor is disconnected (open). The circuit is open if the measured voltage with the pull-up enabled (Vpu) is greater than 1-Volt or if Vpu > Vadc_th. Where Vadc_th is:

Vadc_th = Vsh + (Vdd - Vsh) * 600 / (600 + Rpu)

Vsh is the measured shunt voltage. Rpu is the value of the pull-up resistor, determined during manufacturing and stored in SFLASH. See "21.2.7.3 Shunt resistor open detection of RSx pins" in the architecture TRM for more details.

shows the flow chart for shunt resistor open detection of RSx pins, and

Code Listing 6

shows the code example of main function.

Figure 18. Flowchart of internal temperature calculation

Code Listing 6 Code example of internal temperature calculation

001 int main(void)

002 {

003 ~~~~~~ omitted ~~~~~~

004

005 while (1)

006 {

007

008 ~~~~~~ omitted ~~~~~~

009

010 if (g_diagnosticDataValid)

011 {

012 g_diagnosticDataValid = false;

013 Cy_Adc_GetResult(PACSS_DCHAN2, &diagnosticChannelResult);

014 Adc_DiagnosticHandler(diagnosticConfigs[diagnosticState],

015 diagnosticChannelResult);

016

017 if (diagnosticState == totalDiagnostic)

018 {

019 diagnosticState = 0;

020 }

021 else

022 {

023 diagnosticState++;

024 }

025

026 Adc_SetChannelConfig(PACSS_DCHAN2,

027 diagnosticConfigs[diagnosticState]);

028

029 /* Initiate the second Die Temp measurement */

030 if (DIAGNOSTIC_CHANNEL_CONFIG_DIE_TEMP_UNIT == diagnosticState)

031 {

032 Cy_Adc_PacssMmio_StartSecondaryConversion(PACSS_MMIO);

033 }

034 }

035 ~~~~~~ omitted ~~~~~~

036 }

037 /******************************************************************************

038 * Adc_DiagnosticHandler

039 *******************************************************************************

040 * Call the handler function for the specified diagnostic channel measurement:

041 * - External Temperature

042 * - Internal Die Temperature

043 * - VDIAG vs Ground

044 * - RSH2/RSL2

045 * - Shunt disconnection detect

046 * - SRSS VREF vs Ground

047 * - HPBGR VREF vs Ground

048 ******************************************************************************/

049 void Adc_DiagnosticHandler(adc_diagnostic_config_t state, int32_t result)

050 {

051 ~~~~~~ omitted ~~~~~~

052

053 case DIAGNOSTIC_CHANNEL_CONFIG_RS_OPEN_PULLUP:

054 rshPullup = result;

055 break;

056

057 case DIAGNOSTIC_CHANNEL_CONFIG_RS_OPEN_SHUNT:

058 Adc_RshOpenhandler(rshPullup, result);

059 break;

060

061 ~~~~~~ omitted ~~~~~~

062 }

063 /******************************************************************************

064 * Adc_RshOpenhandler

065 *******************************************************************************

066 * Uses the pull-up and shunt measurements on rsh0 to determine whether or not

067 * the shunt is open

068 ******************************************************************************/

069 void Adc_RshOpenhandler(int32_t vpu, int32_t vsh)

070 {

071 if (Cy_Adc_IsRsOpen(vpu, vsh, ADC_ROOM_TEMPERATURE_CELSIUS))

072 {

073 Example_UartPrintf("RSH Open Detect Failed, RSH is open\r\n");

074 }

075 else

076 {

077 Example_UartPrintf("RSH Open Detect Passed, RSH is NOT open\r\n");

078 }

079 }

080 /*******************************************************************************

081 * Function Name: Cy_Adc_IsRsOpen

082 ****************************************************************************//**

083 * \brief Uses samples of the shunt resistor and pull-up resistor to determine

084 * if the shunt resistor is disconnected (open). The circuit is open if

085 * the measured voltage with the pull-up enabled (Vpu) is greater than

086 * 1 Volt or if Vpu > Vadc_th where Vadc_th is:

087 *

088 * Vadc_th = Vsh + (Vdd - Vsh) * 600 / (600 + Rpu)

089 *

090 * Vsh is the measured shunt voltage

091 * Rpu is the value of the pull-up resistor, determined using the

092 * temperature, based on measured values stored in sflash

093 *

094 * The diagnostic channel uses a gain of 0.5x for these samples. The

095 * values input are multiplied by 2 in this function to correct for

096 * that attenuation.

097 *

098 * \param pullup Result of measuring with the pull-up resistor enabled

099 * \param shunt Result of measuring the shunt without the pull-up

100 * \param temperature Temperature of the die in 12.20 fixed point Celsius. Used

101 * to determine the pull-up value

102 * \param pin Selects which pin is being tested

103 *

104 * \return true if RS open detected

105 * \return false if RS open not detected

106 *******************************************************************************/

107 bool Cy_Adc_IsRsOpen(int32_t pullup, int32_t shunt, int32_t temperature,

108 cy_en_adc_rs_pin_type_t pin)

109 {

110 float pullupMillivolts, shuntMillivolts, adcThreshold, voltageDivider;

111 float rpu;

112 bool result = false;

113

114 pullup = pullup * RS_OPEN_DETECT_GAIN_CORRECTION;

115

116 pullupMillivolts = Cy_Adc_CountsToMillivolts(pullup,

117 CY_ADC_DIAGNOSTIC_CHANNEL, CY_ADC_SAMPLE_RATE_48KSPS, 1.2);

118

119 if (RS_OPEN_DETECT_PULLUP_THRESHOLD_MV < pullupMillivolts)

120 {

121 result = true;

122 }

123 else

124 {

125 rpu = Cy_Adc_GetPullupResistance(pin, temperature);

126

127 shunt = shunt * RS_OPEN_DETECT_GAIN_CORRECTION;

128 shuntMillivolts = Cy_Adc_CountsToMillivolts(shunt,

129 CY_ADC_DIAGNOSTIC_CHANNEL, CY_ADC_SAMPLE_RATE_48KSPS, 1.2);

130

131

132 voltageDivider = RS_OPEN_DETECT_RSH_MARGIN_OHMS + rpu;

133 voltageDivider = RS_OPEN_DETECT_RSH_MARGIN_OHMS / voltageDivider;

134

135 adcThreshold = shuntMillivolts

136 + ((RS_OPEN_DETECT_VDDA_MV - shuntMillivolts)

137 * voltageDivider);

138

139 if (pullupMillivolts > adcThreshold)

140 {

141 result = true;

142 }

143 else

144 {

145 result = false;

146 }

147 }

148

149 return result;

150 }

API details

This chapter explains the details of APIs in shown

Table 5

,

Table 6

and

Table 7

. For more information of all PSoC™ 4 HV PA APIs, see

SDL_psoc4hvpaXXXk.chm

file in SDL path of:

C:/<user path>\ PSoC_Sample_Driver_Library_x.x.x\docs

Start conversion

Description

shows an example of primary vs. secondary conversion. Each sequencer is assigned digital channels. If more than one digital channel is assigned to a sequencer, the sequencer will convert the next assigned channel immediately following the conversion of its previous channel. This is only true if both channels are in incremental conversion mode. In continuous mode, only the lowest channel number will convert.

For example, consider that dchan0 and dchan2 are assigned to sequencer 0 (seq0). When triggered, seq0 will first convert dchan0; on completion it will start the conversion on dchan2. If dchan2 is configured as a secondary channel, when seq0 is triggered (by a primary trigger) only dchan0 will convert.

When a secondary trigger occurs before primary, the secondary channels assigned with the sequencer will go into a pending state. On the following primary trigger, the primary channels will convert followed by the secondary channels.

Figure 19. Primary vs. secondary conversion

APIs

Cy_Adc_StartConversion()

cy_en_adc_error_t Cy_Adc_StartConversion (volatile stc_PACSS_MMIO_t * base)

Description:

Triggers a conversion on the enabled primary channels

In a system with two primary channels connected to two analog channels, both channels are started simultaneously.

In continuous sampling mode, each analog channel should have only one primary channel. If an analog channel has more than one primary channel, only the lowest indexed channel will be used. For example, if

DCHAN [0]

and

DCHAN [1]

are both set as the primary channel for

ACHAN [0]

, only

DCHAN [0]

will be used in continuous sampling mode.

In Incremental sampling mode, each analog channel can have multiple primary channels and they will sample in their index order.

Parameters:

base

– The address of the PACSS MMIO memory

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Cy_Adc_StartSecondaryConversion()

cy_en_adc_error_t Cy_Adc_StartSecondaryConversion (volatile stc_PACSS_MMIO_t * base)

Description:

Triggers a secondary conversion on the enabled secondary channels

Parameters:

base

– The address of the PACSS MMIO memory

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Results and data storage

Description

Each digital channel consists of a result and accumulated result register. The result register is updated when the digital channel completes an acquisition. This may be at the end of the decimator conversion, the end of FIR filtering, or the end of post processing depending on how the channel is configured.

The accumulated result register accumulates signed acquisitions until a configurable threshold is reached. When the threshold is reached the register resets to zero. The accumulated results register can also be written, so that its value can be reset at any time. The accumulated result occurs before the moving average calculation. To obtain an accumulated result the post processor must be enabled.

APIs

Cy_Adc_GetResult()

cy_en_adc_error_t Cy_Adc_GetResult (volatile stc_PACSS_DCHAN_t * base, int32_t * result)

Description:

Reads the value in the result register of the specified channel

The value in the result register is updated after a conversion is completed, including all enabled post processing/filter/correction steps if enabled.

Parameters:

base

– Base address for the digital channel

result

– Output pointer for the result to be saved to

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

or

result

is NULL

Cy_Adc_GetAccumulatorResult()

cy_en_adc_error_t Cy_Adc_GetAccumulatorResult (volatile stc_PACSS_DCHAN_t * base, uint32_t * result)

Description:

Reads the value in the accumulated result register of the specified channel

The value in the accumulated result register is updated after a conversion completed, and does not include the processing from the averaging filter in the DCHAN.

The accumulated result values can be (if enabled):

Gain corrected

Offset corrected

FIR Filtered

Left/right shifted

Parameters:

base

– Base address for the digital channel

result

– Output pointer for the result to be saved to

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

or

result

is NULL

Cy_Adc_ResetAccumulator()

cy_en_adc_error_t Cy_Adc_ResetAccumulator (volatile stc_PACSS_DCHAN_t * base)

Description:

Resets the accumulator to zero

Parameters:

base

– Base address for the digital channel

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPU T_ADDRESS_IS_NULL

if

base

is NULL

Cy_Adc_SetAccumulatorThreshold()

cy_en_adc_error_t Cy_Adc_SetAccumulatorThreshold (volatile stc_PACSS_DCHAN_t * base, uint32_t threshold)

Description:

Sets the accumulator threshold

When the accumulator reaches the specified threshold, the accumulator will reset to zero.

Parameters:

base

– Base address for the digital channel

threshold

– Accumulator threshold

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Ground Reference

Description

shows the block diagram of ground connection for the high-voltage divider (VDIVIDER). Because an accurate measurement of battery voltage is desired, and the device's analog ground may be at a different potential than the battery negative terminal, a ground reference multiplexer for the high-voltage divider. This multiplexer can select vssa, rsh, or rsl pins for measurement and voltage divider ground (vdiv_ret). If the negative pole of the battery is not connected to vssa or it is desired to avoid potential voltage drops across the vssa pin, rsh or rsl (whichever is connected to the battery negative pole) can be selected.

Figure 20. Ground connection for the high-voltage divider

APIs

Cy_Adc_SetGroundReference()

cy_en_adc_error_t Cy_Adc_SetGroundReference (volatile stc_PACSS_MMIO_t * base, cy_en_adc_ground_reference_t select)

Description:

Sets the ground connection for the high-voltage divider

Parameters:

base

– Base address for the PACSS MMIO

select

– Ground reference selection. Options are:

CY_ADC_PACSS_MMIO_GROUND_REFERENCE_VSSA

for VSSA

CY_ADC_PACSS_MMIO_GROUND_REFERENCE_RSH

for RSH

CY_ADC_PACSS_MMIO_GROUND_REFERENCE_RSL

for RSL

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

CY_ADC_ERROR_BAD_PARAM

if

select

is invalid

Sequencer

Description

The PACSS sequencer generates control signals for performing analog-to-digital conversion.

The PACSS has sequencer that is associated with the analog channel. When triggered, the sequencer loads the input pin selection of the first linked digital channel, then starts the decimator, which initializes the modulator to start the conversion. The modulator output data is transferred to the linked digital channel.

APIs

Cy_Adc_EnableSequencer()

cy_en_adc_error_t Cy_Adc_EnableSequencer (volatile stc_PACSS_MMIO_t * base)

Description:

Enables the ADC sequencer and AREF

Enables:

AREF

LDO (modulator voltage source)

PACSS MMIO

Parameters:

base

– Base address for the PACSS MMIO

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Cy_Adc_DisableSequencer()

cy_en_adc_error_t Cy_Adc_DisableSequencer (volatile stc_PACSS_MMIO_t * base)

Description:

Disables the ADC sequencer

Parameters:

base

– Base address for the PACSS MMIO

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Reference

Description

The PACSS has a high-precision bandgap reference (HPBGR) which generates a low-noise 1.2-V reference with ±0.1% accuracy over temperature. An external 470-nF (typ) capacitor is required for the HPBGR reference. This capacitor is connected between VREFH and VREFL pins.

APIs

Cy_Adc_EnableReference()

cy_en_adc_error_t Cy_Adc_EnableReference (volatile stc_PACSS_MMIO_t * base)

Description:

Configures and enables the high-precision band gap reference (HPBGR)

The HPBGR is configured to:

Enable circuit chopping

Chopping phase between the BGR core and the output buffer are reversed

External capacitor compensation is enabled

About the BGR core and output buffer chopping: The HPBGR contains a "band gap reference core" (BGR core) and an output buffer, which are circuit-chopped to reduce offset error.

The offset is reduced most when the BGR core uses the opposite clock edge to chop when compared to the output buffer, which is referred to here as the reverse phase.

Optionally, the BGR core and the output buffer can use the same clock edge for circuit chopping, referred to here as the normal chopping phase.

Parameters:

base

– Base address for the PACSS MMIO

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

or

result

is NULL

Cy_Adc_DisableReference()

cy_en_adc_error_t Cy_Adc_DisableReference (volatile stc_PACSS_MMIO_t * base)

Description:

Disables the high-precision band gap reference (HPBGR)

Parameters:

base

– Base address for the PACSS MMIO

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

or

result

is NULL

Interrupt

Description

Each digital channel contains the following interrupts:

RANGE_INTR

: Range detect Interrupt: hardware sets this interrupt if the conversion result of that channel met the condition specified by the RANGE_LOW and RANGE_HIGH registers. Write with '1' to clear bit

ACC_THRESH_INTR

: Accumulated threshold interrupt: hardware sets this interrupt when the accumulated threshold value has been surpassed

SATURATE_INTR

: Saturate interrupt: hardware sets this interrupt if a conversion result is prevented from overflowing in either the decimator or the post processor when

PP_CTL.SAT_EN=1

. Write with '1' to clear bit

OVERLOAD_INTR

: Overload interrupt: hardware sets this interrupt for each channel if the modulator output is all zeros or all ones. This is an indication that the modulator is overloaded. Write with '1' to clear bit

HWT_COLLISION_INTR

: Hardware trigger collision interrupt 0: hardware sets this interrupt when the HW trigger signal is asserted while the DSM is BUSY. Raising this interrupt is delayed to when the scan caused by the HW trigger has been completed, i.e., not when the preceding scan with which this trigger collided is completed. When this interrupt is set, it implies that the channels were sampled later than was intended (jitter). Write with '1' to clear bit

FWT_COLLISION_INTR

: Firmware trigger collision interrupt 0: hardware sets this interrupt when

FW_TRIGGER

is asserted while the DSM is BUSY. Raising this interrupt is delayed to when the scan caused by the

FW_TRIGGER

has been completed, i.e., not when the preceding scan with which this trigger collided is completed. When this interrupt is set, it implies that the channels were sampled later than was intended (jitter). Write with '1' to clear bit

OVERFLOW_INTR

: Overflow interrupt: hardware sets this interrupt when it sets a new

DATA_VAL_INTR

while that bit was not yet cleared by the firmware. Write with '1' to clear bit

DATA_VAL_INTR

: Data Valid Interrupt 0: hardware sets this interrupt after completing a scan of all the enabled channels. Write with '1' to clear bit

APIs

Cy_Adc_GetInterrupt()

cy_en_adc_error_t Cy_Adc_GetInterrupt (volatile stc_PACSS_DCHAN_t * base, uint32_t * result)

Description:

Gets the specified digital channel's interrupt status

Parameters:

base

– Base address for the DCHAN MMIO

result

– Output variable for the DCHAN interrupt status

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

or

result

is NULL

Cy_Adc_GetInterruptMasked()

cy_en_adc_error_t Cy_Adc_GetInterruptMasked (volatile stc_PACSS_DCHAN_t * base, uint32_t * result)

Description:

Gets the DCHAN interrupt status masked by the enabled interrupts

Parameters:

base

– Base address for the DCHAN MMIO

result

– Output variable for the DCHAN interrupt status

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

or

result

is NULL

Cy_Adc_SetInterruptMask()

cy_en_adc_error_t Cy_Adc_SetInterruptMask (volatile stc_PACSS_DCHAN_t * base, cy_en_adc_dchan_interrupt_t interrupt)

Description:

Enables the specified interrupt type for the specified channel

Parameters:

base

– Base address for the DCHAN

interrupt

– Interrupt to enable. Options are:

CY_ADC_DCHAN_INTERRUPT_DATA_VAL

CY_ADC_DCHAN_INTERRUPT_OVERFLOW

CY_ADC_DCHAN_INTERRUPT_FIRMWARE_TRIGGER_COLLISION

CY_ADC_DCHAN_INTERRUPT_HARDWARE_TRIGGER_COLLISION

CY_ADC_DCHAN_INTERRUPT_OVERLOAD

CY_ADC_DCHAN_INTERRUPT_SATURATE

CY_ADC_DCHAN_INTERRUPT_ACCUMUlATION_THRESHOLD

CY_ADC_DCHAN_INTERRUPT_RANGE

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_BAD_PARAM

if

interrupt

is invalid

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Cy_Adc_ClearInterrupt()

cy_en_adc_error_t Cy_Adc_ClearInterrupt (volatile stc_PACSS_DCHAN_t * base, cy_en_adc_dchan_interrupt_t interrupt)

Description:

Clears the specified interrupt

Parameters:

base

– Base address for DCHAN

interrupt

– Interrupt to clear. Options are:

CY_ADC_DCHAN_INTERRUPT_DATA_VAL

CY_ADC_DCHAN_INTERRUPT_OVERFLOW

CY_ADC_DCHAN_INTERRUPT_FIRMWARE_TRIGGER_COLLISION

CY_ADC_DCHAN_INTERRUPT_HARDWARE_TRIGGER_COLLISION

CY_ADC_DCHAN_INTERRUPT_OVERLOAD

CY_ADC_DCHAN_INTERRUPT_SATURATE

CY_ADC_DCHAN_INTERRUPT_ACCUMUlATION_THRESHOLD

CY_ADC_DCHAN_INTERRUPT_RANGE

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_BAD_PARAM

if

interrupt

is invalid

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL

Cy_Adc_GetInterruptCause()

cy_en_adc_error_t Cy_Adc_GetInterruptCause (volatile stc_PACSS_MMIO_t * base, cy_en_adc_interrupt_t source, cy_en_adc_interrupt_cause_t * cause)

Description:

Gets the interrupt cause

This function reads the

PACSS_MMIO INTR_CAUSE

register and stores the results in the cause parameter.

This interrupt is the logical OR of all available interrupts in the PACSS. Interrupts must have their interrupt mask enabled in their respective blocks.

Parameters:

base

– Address of the PACSS MMIO registers

source

– Interrupt Source. Valid inputs are:

CY_ADC_PACSS_MMIO_INTERRUPT_DCHAN0

CY_ADC_PACSS_MMIO_INTERRUPT_DCHAN1

CY_ADC_PACSS_MMIO_INTERRUPT_DCHAN2

CY_ADC_PACSS_MMIO_INTERRUPT_DCHAN3

Cause:

Pointer to the interrupt cause return parameter. Values returned are:

CY_ADC_PACSS_MMIO_INTERRUPT_CAUSE_IDLE

CY_ADC_PACSS_MMIO_INTERRUPT_CAUSE_ACTIVE

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_BAD_PARAM

if

source

is invalid

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL or

cause

is NULL

Offset and Gain Correction

Description

Offset and gain correction are enabled via the

OCOR_EN

and

GCOR_EN

bits. If offset correction is enabled, the 16-bit OCOR value is left shifted by the

OCOR_SCLR

value then added to the decimation result.

If gain correction is enabled, the decimated result is multiplied by the 16-bit GCOR value. The 4-bit GVAL field is used to determine how many bits of the GCOR value are valid in the calculation. If both offset and gain correction are enabled, the offset calculation is done before the gain multiplication.

If auto gain control is enabled, the offset and gain correction are taken from

PACSS_MMIO_OFST_COR1

and

PACSS_MMIO_GAIN_COR1

registers.

APIs

Cy_Adc_SetGainCorrection()

cy_en_adc_error_t Cy_Adc_SetGainCorrection (volatile stc_PACSS_DCHAN_t * base, uint16_t gain)

Description:

Sets the gain correction factor for the specified DCHAN

This function sets the GCOR value of the specified digital channel. It assumes 15 valid bits since that is what the calibration values stored in supervisory flash use.

Parameters:

base

– Address of the DCHAN registers

gain

– Gain correction factor

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_BAD_PARAM

if

source

is invalid

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL or

cause

is NULL

Cy_Adc_SetOffsetCorrection()

cy_en_adc_error_t Cy_Adc_SetOffsetCorrection (volatile stc_PACSS_DCHAN_t * base, int16_t offset)

Description:

Sets the offset correction factor for the specified DCHAN

This function sets the OCOR value of the specified digital channel.

Parameters:

base

– Address of the DCHAN registers

gain

– Gain correction factor

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_BAD_PARAM

if

source

is invalid

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL or

cause

is NULL

Cy_Adc_SetAGCGainCorrection()

cy_en_adc_error_t Cy_Adc_SetAgcGainCorrection (volatile stc_PACSS_MMIO_t * base, uint16_t index, uint16_t gain)

Description:

Sets the gain correction factor for the specified AGC gain level

This function sets the GCOR value of the specified AGC level. It assumes 15 valid bits since that is what the calibration values stored in supervisory flash use

Parameters:

base

– Address of the PACSS_MMIO registers

index

– AGC gain level

gain

– Gain correction factor

Returns:

CY_ADC_ERROR_NONE

if no errors occur

CY_ADC_ERROR_BAD_PARAM

if

source

is invalid

CY_ADC_ERROR_INPUT_ADDRESS_IS_NULL

if

base

is NULL or

cause

is NULL

Cy_Adc_SetAgcOffsetCorrection()

cy_en_adc_error_t Cy_Adc_SetAgcOffsetCorrection (volatile stc_PACSS_MMIO_t * base, uint16_t index, uint16_t offset)